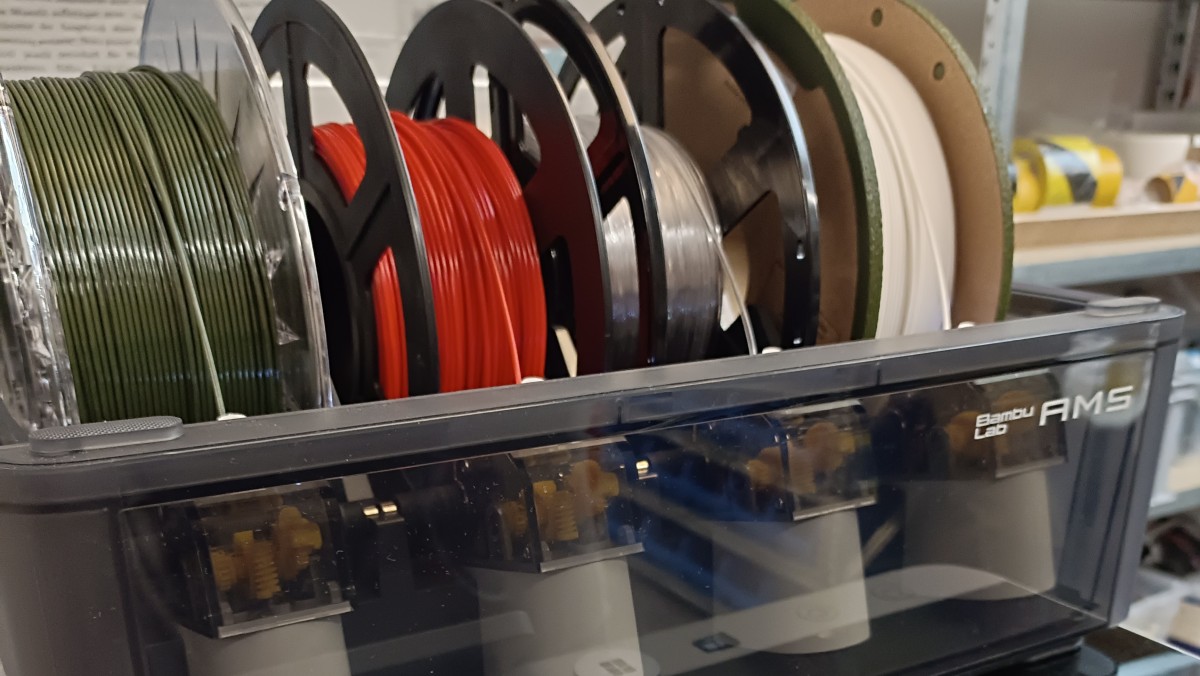

This post is part of a series in which we want to present some of our new and valuable material that we were able to procure due to a grant by Deutsche Stiftung für Engagement und Ehrenamt.

Back in the old place, when we were thinking about how best to describe ourselves, we came up with this phrase: “A hacking and making space with embroidery, knitting and sewing machines […].”

Knitting and sewing machines have kept kind of happening to us over time, so we have built up a veritable machine park.

Only the combined sewing and embroidery machine purchased at the end of 2016 from the municipal start-up funds has no longer been available to us since our forced moving out from Ulm.

So it was all the more obvious for us to buy a new one.

Embroidery machines are a very wild business.

There are sewing machines with an embroidery module – like the one we bought at Weinhof – and there are very professional machines with 10 or more needles, which we felt were intended for the mass production of embroidered textiles.

It turned out from our practical experience that neither end of that spectrum really suited our needs.

We were never really satisfied with the combined sewing and embroidery machine from Weinhof, because although it sews great, the embroidery mode always felt a bit like a compromise.

With the experience we have gained, however, we have now been able to say more precisely what we want: A machine that is easy to use, but is still first and foremost a real embroidery machine, so that we can embroider as many different things as possible with it.

In the end, we chose the Brother PR1X, and so far it has met our expectations very well and is being used pretty regularly.

As with the previous Husky, there are some included borders and fonts that can be selected directly on the machine and then embroidered – but to be honest, some of these designs seem a bit out of place nowadays.

Of course, you can also read files from a USB stick and then embroider them.

As always, this requires special software from the manufacturer, which costs extra money.

In addition, such proprietary software contradicts our principle of Free Knowledge and Free Software and the associated social freedoms: Everyone should be able to use this machine and control it from their computer.

Fortunately, there is a dedicated embroidery machine community that has developed the Inkscape plugin Ink/Stitch.

This allows you to draw or import vector graphics with the free graphics software Inkscape and then convert them into machine code for the appropriate embroidery machine.

This means that anyone can design their own patterns, logos, pictures or other ideas and then embroider them.

Of course, we have already tried it out and spread our Zelti on all kinds of fabrics.

At this point, a big hurrah to Free Software and everyone who contributed to this plugin.

A big drawback with the old embroidery machine was that the free alternatives were not so easy to use back then, so designing the things to be embroidered was a big hurdle.

With Inkscape and Ink/Stitch, we can now use even an impressive machine like the PR1X just like that.

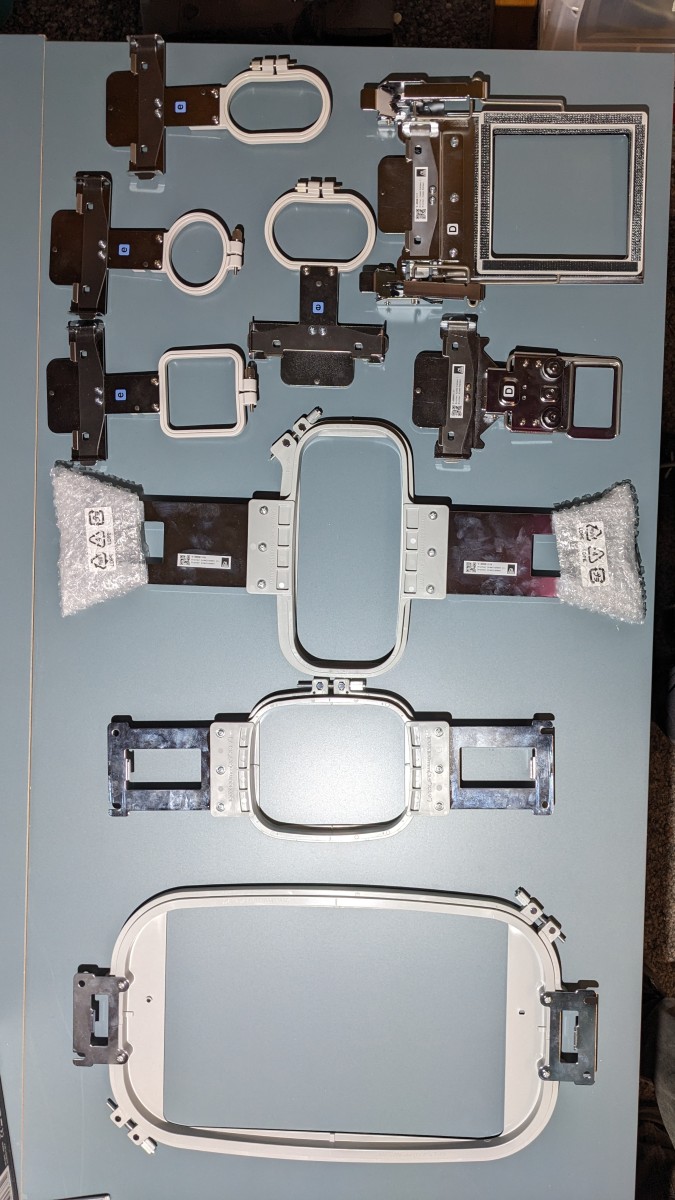

Let’s go back to the hardware aspect: The fabrics you want to embroider are clamped into a frame, which is then attached to the machine.

With the old sewing and embroidery machine, this frame was always built into the design of the classic sewing machine.

This made it difficult or even impossible to embroider hoodies, for example.

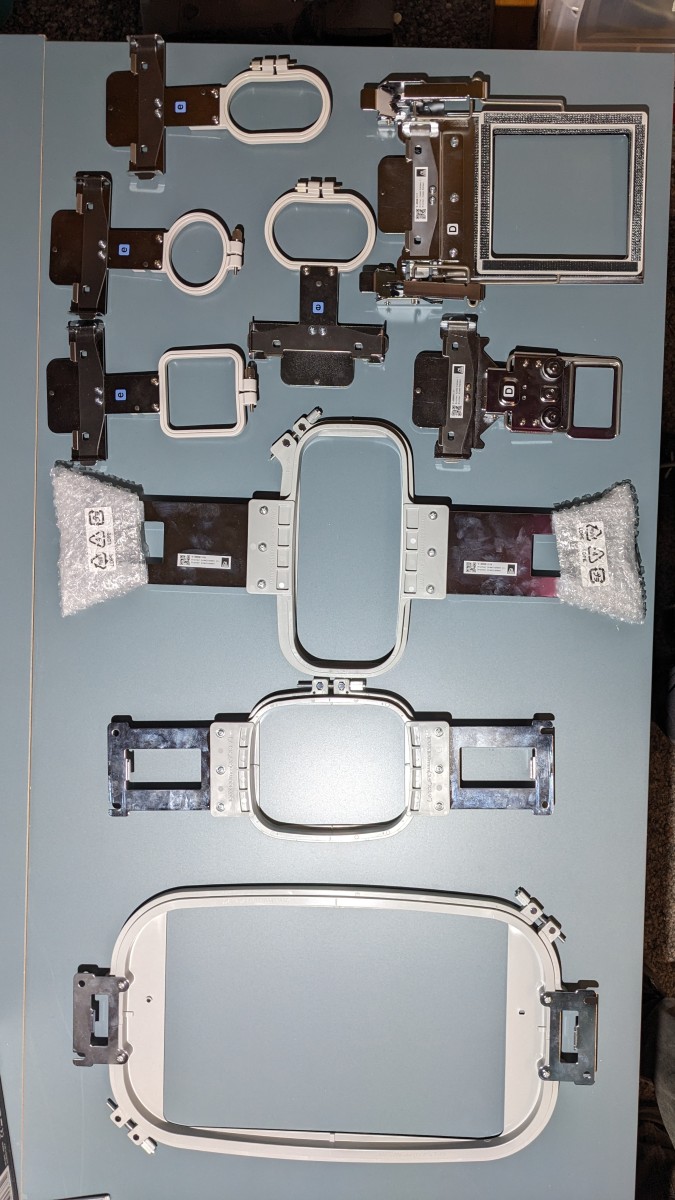

With the new machine, we now have nine embroidery hoops in different sizes and a machine that has been designed for embroidery from the outset.

This means that pieces of fabric of any size can now be embroidered.

Anyone who wants to use the new embroidery machine is welcome to come along to one of our sewing cafés or Maker Mondays and have fun with it after an introduction!